Iron pour event turns up the heat for students on chilly spring afternoon

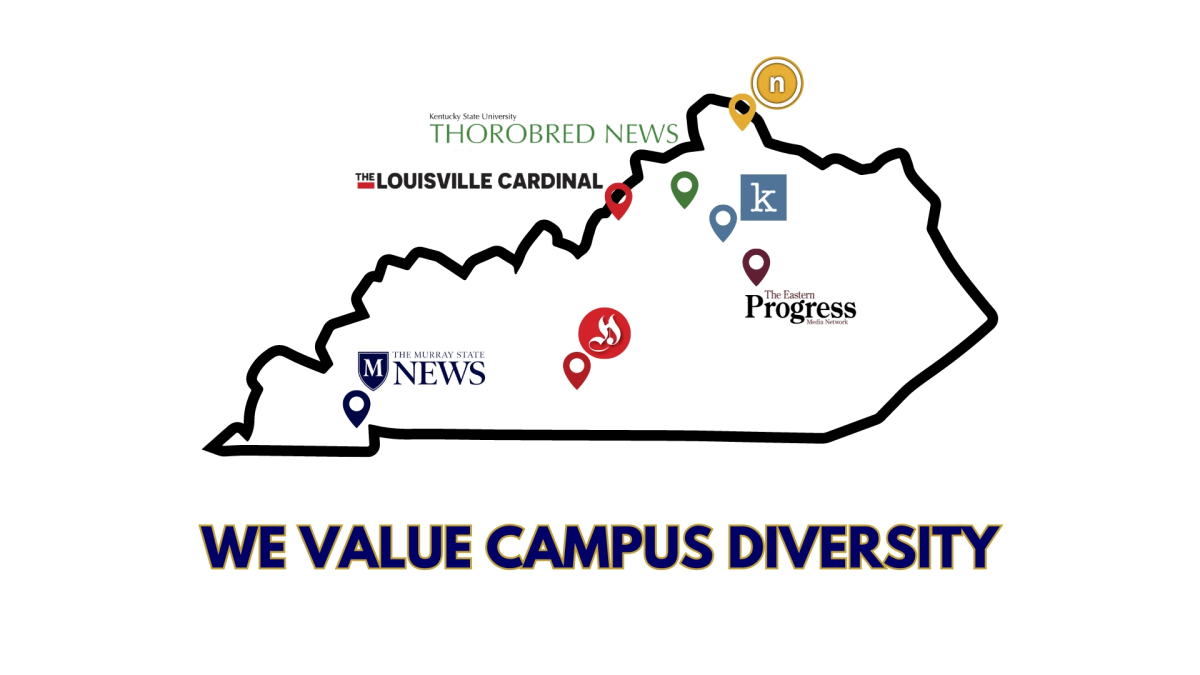

Art studio senior Amy Hoagland, left, works on the iron pour, which drew artists from Wisconsin, Florida, Colorado and West Virginia.

April 9, 2016

Creating art is a way to bring communities together and share rich traditions from one generation to another. UK’s School of Art and Visual Studies held a spring iron pour Saturday afternoon, which brought together students, professors and artists from all over the country to cast iron sculptures.

An iron pour is when iron is heated in a furnace and poured into molds. When the molds are removed, a sculpture remains. The spring iron pour was held inside the Metal Arts Building and outside the Reynolds Building.

Work was done all over the site, from breaking iron into smaller pieces to putting final touches on molds before casting. Art studio senior Amy Hoagland and art studio and arts administration senior DaHee Son weighed iron into charges.

“Each charge is the amount of iron you put into the furnace at once,” Hoagland said.

For the furnace at the iron pour, charges weighed 315 pounds.

Son created a mold to be filled at the iron pour.

“(The sculpture is) like hands, but dismantled,” she said.

The final piece will be interactive and will have a concrete board with the iron parts.

While creating the iron art, safety is a main concern. Participants wore face masks, safety glasses, gloves and leather outfits in case sparks started to fly.

Lecturer Jeremy Colbert said iron casting came to UK 23 years ago. Since then, the university has become a flagship among colleges that offer iron casting and brings together a community of artists.

“Iron (casting) is kind of like a subculture,” Colbert said. “In the last 10 or 15 years, it’s really blown up.”

Colbert said UK has led advancements in iron work, such as developing 3-D printing and chemical testing.

“We’re bridging the new with the old traditional stuff,” he said.

Colbert said artists from Wisconsin, Colorado, Florida and West Virginia were in attendance at the event, which also featured many UK alumni.

The scrap iron at the iron pour was donated to the School of Art and Visual Studies’ metalwork program.

“This metal particularly came from the … University of Kentucky president’s home,” said Colbert, noting how the Physical Plant Division donated radiators left over from renovations to Maxwell Place.

Colbert and his peers created the furnace used during the iron pour, TWO4, during their graduate school work at Florida State University. When FSU wanted to retire the furnace, Colbert brought it to UK. An estimated 38 tons of metal has been put into TWO4.

“It’s got a long legacy,” Colbert said. “Now, that legacy has been brought to Kentucky.”