Local focus, global stage for Kentucky AgTech company

February 16, 2021

Turn left off of 1-64 exit 133 onto Kentucky 801, and your eyes will immediately look north, where a warm bronze glow occupies much of the horizon.

That glow is no illusion – it’s the $15 million LED light display inside AppHarvest’s flagship facility. At nearly 3 million square feet, the greenhouse is the largest of its kind in the world and can grow 50 million pounds of produce a year.

AppHarvest was founded by UK alum Jonathan Webb in 2017. The Morehead greenhouse was fully operational In October 2020 and in January 2021 they harvested their first round of tomatoes, which went to retailers like Kroger, Publix and Wal-mart. Two weeks ago the company went public on the Nasdaq and is now trading at $33.26 a share.

“The fact that we were able to do this, in the middle of a global pandemic, has been just a true testament to the region, and the ingenuity, tenacity and grit of the region, who really helped make this possible,” Webb said. But Webb and his team don’t want to peak in public stock options.

The physical glow from their greenhouse’s cutting-edge design could very well serve as a metaphor for AppHarvest’s mission – to be a warm beacon of light for all Kentuckians.

“When people are talking about rebuilding agriculture, using technology, aligning with nature, and the fact that they’re talking about more in Kentucky, it’s just phenomenal. And that energy, you feel it,” Webb said. “There’s support from community members across the region.”

AppHarvest has support beyond the local community – Kentucky Gov. Andy Beshear also gave his stamp of approval to the business.

Beshear and a crop of university and industry experts toured the Morehead facility on Feb. 9, 2021.

“They believe in this industry. They believe in feeding the people of America with clean, efficient, nutritious produce. And they believe in bringing more jobs to this part of our great state because it’s the right thing to do,” Beshear said in a press conference following the tour, calling the greenhouse a “technological marvel.”

AppHarvest expects to bring several hundred more jobs to Eastern Kentucky in the next year after breaking ground on a similarly large facility in Madison County and a 15-acre leafy greens farm in Berea. With a goal of opening 12 facilities by 2025, AppHarvest could bring nearly a thousand “high tech” entry level jobs to the region if scaled similarly to the Morehead location.

They currently employ more than 300 people at the flagship and provide a living wage and full healthcare coverage to everyone. Those benefits are part of what Webb calls “redefining the dignity of work in agriculture.”

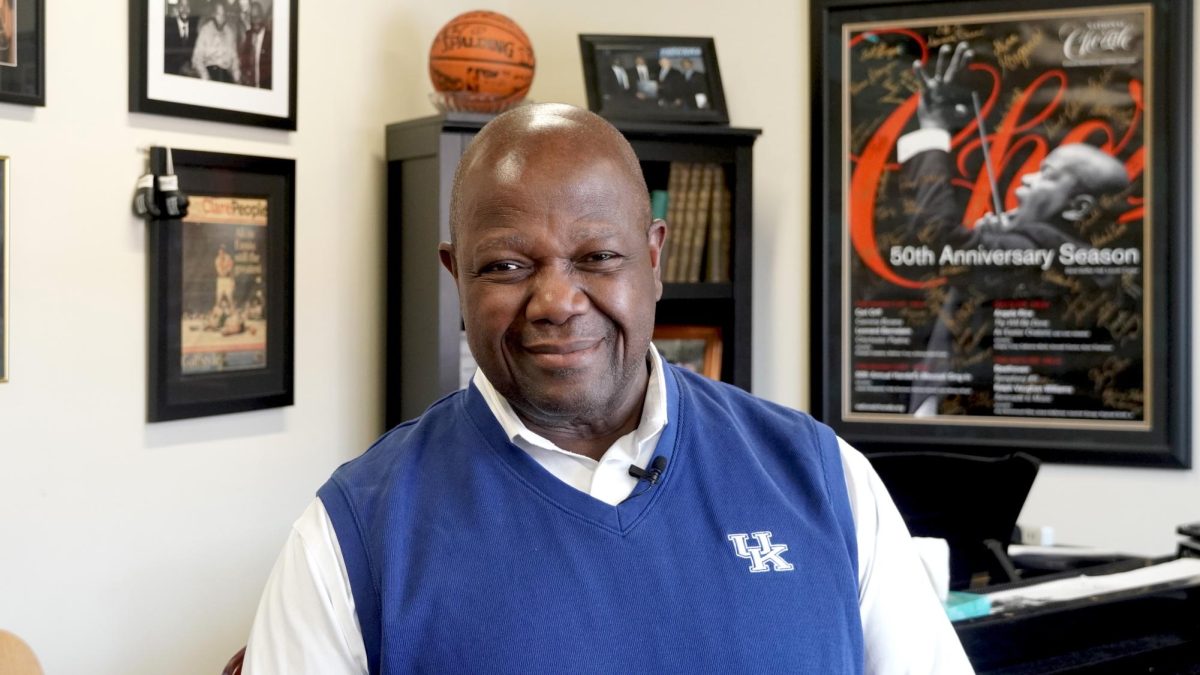

“If they can continue down the path that they are going on, and they expand at the rate that they’re talking about the workforce that they’re going to need is substantial. And so it creates great job opportunities, and you know, it really could be transformative in agriculture in our state to have this,” said Mark Williams, the chair of UK’s horticulture department.

Williams was part of the AppHarvest contingent that traveled to the Netherlands in February of 2020 to learn about the nation’s approach to high intensity agriculture. Denmark exports the second most food by dollar value in the world despite its small size, and that’s due to their technological approach.

“We were all of course blown away and saw that there was a great opportunity for doing the same kind of thing in Kentucky,” Williams said.

Denmark also attributes its success to what Williams called a “triple helix” – a partnership between industry, government and education.

“We had a lot of shared interest in thinking about ways that we can help to develop farming systems that that push the needle towards a more sustainable way of thinking about food production,” Williams said.

As an education partner, the horticulture department at UK has since had room to hire a faculty person, Garrett Owen, specializing in controlled environment research that can address avenues that would directly impact AppHarvest.

UK employees like Owen, Williams and even computational science experts are forming a research group to target the AgTech industry.

“We’re trying to look at, you know, reducing their waste stream and things like that as they get going,” Williams said. “There’s leakage in some of the wastes, the way they harvest things and stuff. So we’ll focus in on specific questions, and then we’ll pull the right people together at UK to put together teams to be able to do research to help them.”

Williams also said it would be a “no brainer” for horticulture students at UK to work with AppHarvest and that his department is looking at an internship program.

“It should be easy for UK students that with a little bit of training to go get jobs there,” Williams said. “So it’s definitely on our horizon of using this as a recruiting tool, but also as a as a pipeline for students to come get degrees in horticulture science and then go work at AppHarvest.”

Higher education outreach isn’t the end of the road for either Williams or AppHarvest. They also want to work with students at the high school level.

Following the greenhouse tour, Webb and Beshear announced an expansion of AppHarvest’s container farm program to two more high schools in Kentucky.

The containers are a joint project with financial services company Cowen and, at 2,880 cubic feet, can grow more than 8,000 mature plants at a time.

Rockcastle High School was named one of the new recipients of a container farm. Agriculture teacher Mark Whitaker said they expect it to be ready for next school year.

“On Monday we had come to an agreement and had it all all in motion and everything so it happened very quickly,” Whitaker said. “Obviously we’re really excited about it and so is the superintendent of the school, she was very supportive, and Mr. Bussell the principal he was very supportive and they just ran with it.”

Whitaker said he does not know yet what they will grow but the container farm can support lettuce, spinach, kale and root vegetables like carrot and radish.

“Whatever produce we grow will be used in school lunches in our district. I know in Rowan County, they were one of the first schools to do this and they were growing enough lettuce for their entire school district out of the container so that it will be something similar to that,” Whitaker said.

Feeding Kentuckians fresh healthy food is a goal of the container program, Webb acknowledged, along with steering high school students to the AgTech industry.

“I hope that we will have students that will seriously look at that as a career, and consider going into that field and possibly working for that company,” Whitaker said. I think their motivations for doing this, are partly based on training potential workforce for the future.

Whitaker said that Rockcastle already has a greenhouse program at the school where they grow starter plants and bedding flowers as a fundraiser, but only in the spring.

“The big thing as far as curriculum and stuff that that the container farm is going to do for us is we’ll be able to do stuff year round, because really the greenhouse sales that we do are pretty much a spring only thing,” Whitaker said.

Webb hopes the booming AgTech wave in Kentucky will inspire students to invest in the Commonwealth.

“That’s nearly $100,000 investment of physical equipment,” Webb told Rockcastle students during the presser. “We believe in you. You are the future. Me, people like the governor, political leaders in Frankfort, we’re going to come and go. You’re the leader. This is your state.”

Beyond education, Webb plans to make an impact on the state by supporting non-profits with healthy fruits and vegetables, especially during COVID-19.

“CDC has reported one in 10 Americans do not eat enough fruits and vegetables,” Webb said. “So whatever we can do to play our part and make sure that good, healthy, affordable, fresh fruits and vegetables are available to everyone is a core part of our mission.”

How AppHarvest grows its food matters to the company too.

As Webb explained during the tour, the Morehead greenhouse is not connected to the community water system because they didn’t want to take resources or push in waste.

Instead, they have a 1.8 million gallon tank that collects water from the roof. AppHarvest uses 90% less water than traditional agriculture but has up to 30 times higher yields.

Vice president of production Tim Robinson explained how that thoughtfulness relates to the growing process.

“We’re recycling the whole time,” Robinson said during the tour. He walked the visitors through the greenhouse’s use of integrated pest management, a sustainable and chemical-free way to balance crops.

Robinson described it as using good bugs to get bad bugs and good fungi to get bad fungi. They control nutrients down to the microbe, and bee hives are scattered throughout the greenhouse to help pollination as well.

“They’re friendly,” Webb told the governor as the peeked into a hive on the tour.

AppHarvest has a computer program that can update employees on IPM. The system runs at night and can forecast the weekly harvest down to the exact number of heads and flowers.

According to Robinson, they harvest two or three times a week since different sections of the greenhouse ripen at different times because the light comes in at different wavelengths.

Tomato heads are kept under light year-round and grow a foot a week, Robinson said. Their growth is supported by wires that employees cinch higher as need, since Webb said the vines can be almost 45 feet tall.

Webb described AppHarvest’s approach as “driving nature from behind with technology.”

Tech extends past the farming itself; robotic carts transport produce through the facility. Ergonomic lifts keep employees from crouching down to work AppHarvest aims to cut down on food waste by using a digital model to inspect its supply chain.

“What we’re doing matters,” Webb said. “The way we’re working to transform agriculture matters, but the place in which we’re doing it might be the most important and that’s the exciting thing is that we can continue to build and grow the company inside of the region that we love.”